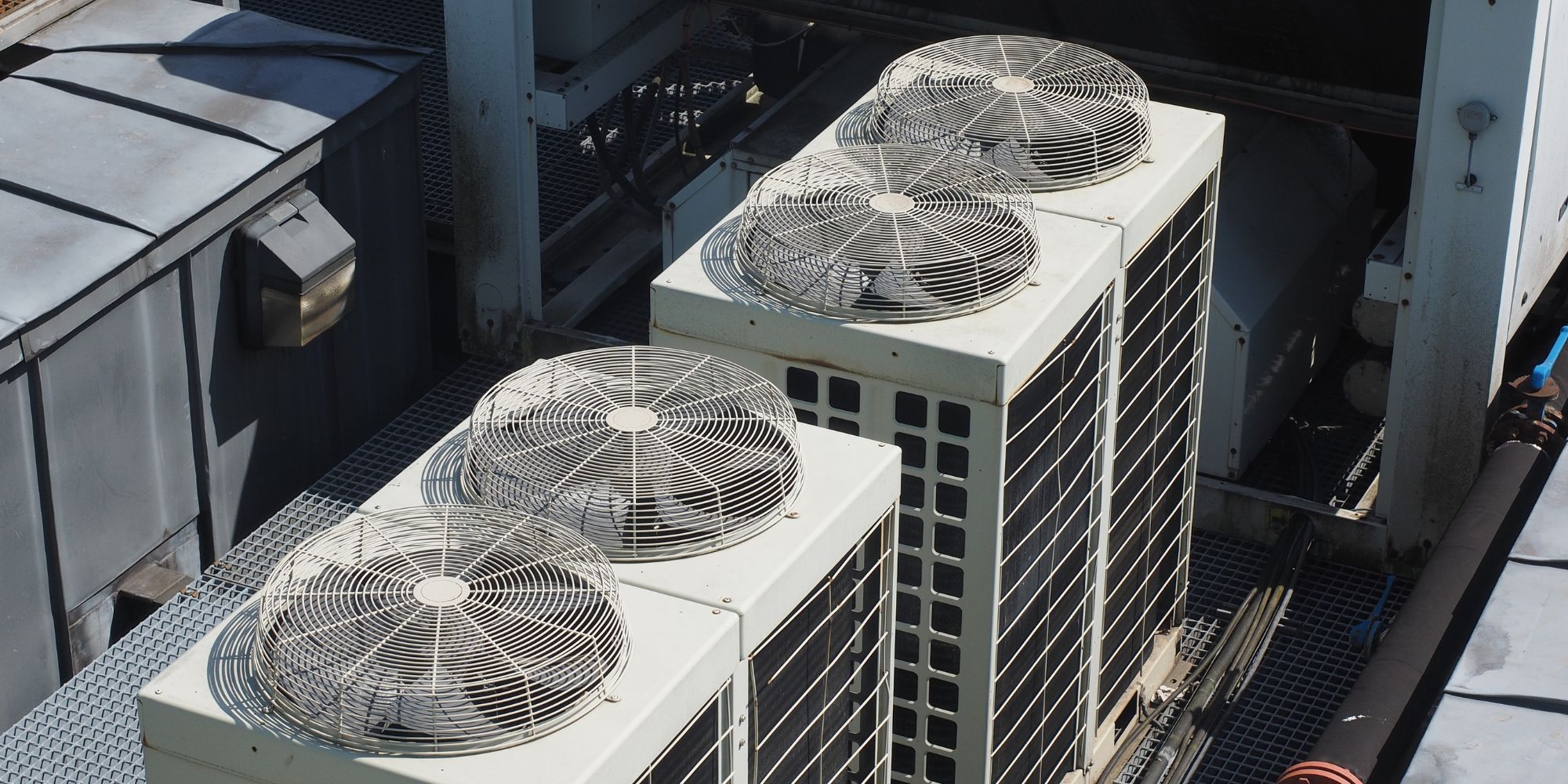

Energy efficiency of HVAC systems

HVAC systems (Heating, Ventilation, and Air Conditioning) ensure thermal comfort and proper air quality indoors. They are also responsible for maintaining stable technological conditions, which directly affect production efficiency and workplace safety. In some cases, they also account for a significant share of total energy consumption in facilities. Optimizing these systems is not only a way to reduce energy costs but also a key element of strategies aimed at improving energy efficiency and reducing greenhouse gas emissions.

What is an HVAC system and where is it used?

HVAC stands for Heating, Ventilation, and Air Conditioning. In industrial facilities, these systems are designed to:

- maintain optimal temperature in production halls and warehouses,

- ensure proper air circulation,

- regulate humidity and filter air (crucial in processes sensitive to contamination),

- cool equipment and technological spaces.

HVAC systems are used not only in production halls but also in technological areas, warehouses, and employee facilities. Their role is particularly important in industries requiring strict environmental control, such as pharmaceuticals, food processing, electronics, and chemicals. In some cases, they are also responsible for cooling machinery or recovering heat from industrial processes.

When do HVAC systems consume more energy?

In a typical industrial plant, increased energy use by HVAC systems results from:

- outdated equipment with low efficiency,

- lack of automation to adjust operation to actual demand,

- poor system maintenance (e.g., dirty filters, leaky air ducts),

- continuous operation of equipment regardless of occupancy or production conditions,

- no energy recovery from exhaust air or technological processes.

Modernizing HVAC systems - what is worth implementing?

To ensure efficient operation of HVAC systems, it is worth considering one or more of the commonly applied solutions:

- Monitoring and control systems

Implementing a Building Management System (BMS) allows for dynamic control of temperature and output depending on changing conditions - both indoors and outdoors. This limits unnecessary equipment operation and enables more precise adaptation to production needs.

- Replacing equipment with modern units

Upgrading equipment may include replacing chillers, fans, or heaters with new, high-efficiency units. Selecting appropriately sized components reduces energy consumption while maintaining the technical parameters required by production processes.

- Use of variable frequency drives

Using motors with variable frequency drives (VFDs) enables smooth adjustment of equipment performance, such as pumps and fans. This helps reduce excess flow, which in standard systems often leads to unnecessary energy use.

- Heat recovery and air reuse

Recovering heat from exhaust air using recuperators can partially meet the demand for heating energy in the supply system. Combined with free cooling - using cool outdoor air to support air conditioning—it can significantly reduce operating costs.

- Thermal modernization or building insulation improvements

Modernization efforts should also include thermal upgrades of the building and HVAC distribution networks. Insulating ducts and pipes, as well as improving the tightness of partitions and industrial gates, helps reduce energy losses, which often go unnoticed in system analyses.

What benefits does HVAC modernization bring?

Improving the efficiency of HVAC systems translates into a range of measurable benefits for companies:

- reduced energy consumption,

- lower operating costs in the short term,

- reduced CO2 emissions and compliance with sustainability goals,

- improved reliability and predictability of installations,

- better control of climatic conditions and greater employee comfort,

- reduced risk of downtime caused by system failures.

The final outcome depends on the individual conditions of the plant, the scope of modernization, and the quality of implemented solutions. In practice, even partial optimization can deliver noticeable energy savings and enhance the competitiveness of a facility.

Take a step towards cost-effective decarbonization of your business

Contact usSummary

Enhancing the energy efficiency of HVAC systems in industry is one of many ways to reduce energy use and operating costs, and it can go hand in hand with other solutions - such as heat recovery. Modernizing these systems not only enables quick savings but also helps meet decarbonization and climate policy requirements. By implementing the right technologies, industrial plants can achieve tangible financial benefits while improving operational efficiency.