Heat recovery from compressors

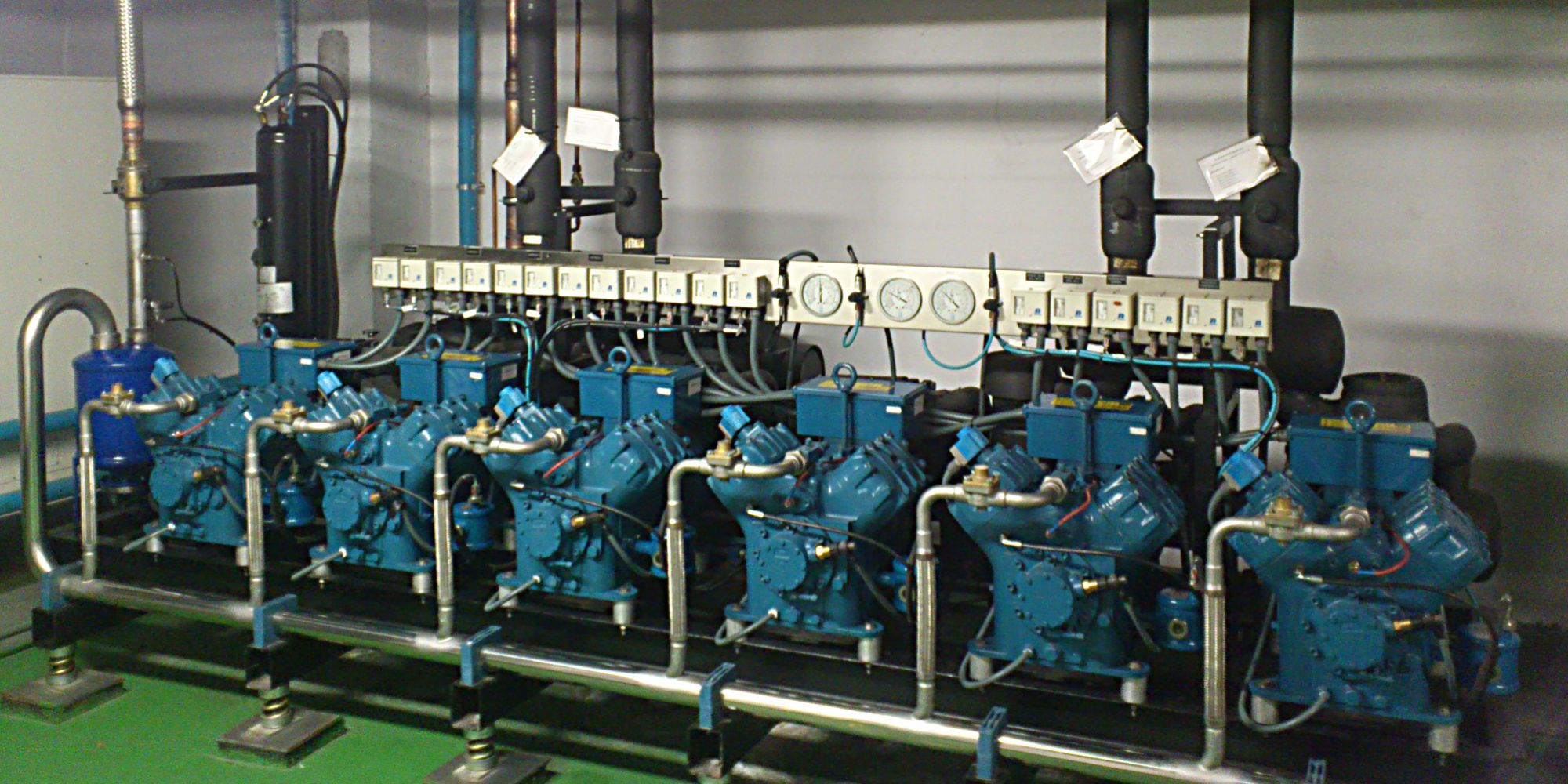

Compressor systems are commonly used in various industrial sectors such as manufacturing, processing, and refrigeration, generating large amounts of waste heat. With appropriate technological solutions, this heat can be effectively recovered and reused in production processes.

How to recover heat from compressors?

Compressors are commonly used in various industries, such as manufacturing, processing, and refrigeration, where they generate significant amounts of waste heat. Modern technologies enable effective recovery of this heat, allowing it to be reused in production processes.

During compressor operation, thermal energy is generated, which is usually lost to the environment. Heat recovery involves capturing this heat and converting it into useful energy, e.g., for heating water or air. The two most commonly used solutions are heat exchangers and water cooling. Heat exchangers are a technology where waste heat is transferred to water heating, air heating, or other media used in company processes. In places where water is used for cooling equipment in the technological process, heat can also be recovered. It is transferred to water, which can then be used for building heating, as process water, or in production processes.

Examples of heat recovery from compressors

Example 1: food production plant

In a food production plant, a heat recovery system from air compressors enabled heating of process water used for cleaning equipment, resulting in a 30% energy cost savings for the company. The plant with compressor power of 242 kW recovers 170 kW of heat, translating into an annual saving of approximately 762,412 kWh.

Numerical data:

- Compressor power: 242 kW

- Recovery power: 170 kW

- Annual energy savings: 762,412 kWh

Example 2: chemical industry

In the chemical industry, waste heat from compressors with a power of 1,000 kW was used for heating buildings and technological processes, reducing heating costs by 40% and lowering CO2 emissions. Annual savings amount to 6,278,000 kWh.

Numerical data:

- Compressor power: 1,000 kW

- Amount of recovered heat: 793 kW

- Annual savings: 6,278,000 kWh of energy

What are the benefits of heat recovery from compressors?

Companies can expect significant financial and environmental benefits from implementing heat recovery technologies. Primarily, these include lower energy bills, improved energy efficiency, and reduction of CO2 emissions. Additionally, recovered heat can improve working comfort, and companies gain a competitive advantage due to lower operating costs and higher efficiency.

Before investing in heat recovery systems, a preliminary analysis and energy audit are necessary to identify the best places for implementing such technologies. Proper selection of recovery technology and its integration with existing plant systems is also important. The investment involves initial costs, which can be partially offset by available forms of support such as grants or energy efficiency programs.

Although investing in heat recovery systems can bring significant savings, initial costs may be high. It is worth considering available financing options such as ESCO, grants, tax reliefs, or support programs for companies investing in energy efficiency.

Summary

In summary, the planning process for investments should take into account regulations concerning energy efficiency and environmental protection, which may offer additional financial or regulatory benefits. Heat recovery from compressors is a process that requires careful planning and execution. It enables significant reduction of operating costs and decreases CO2 emissions. This investment can pay off quickly, and its benefits will be felt for many years. Striving for energy efficiency will not only bring tangible savings but also contribute to sustainable development of the company, which is increasingly appreciated by clients and stakeholders.