Trigeneration – the combined production of cooling, heat, and electricity

Trigeneration is a solution that allows companies to maximize fuel energy use by simultaneously producing electricity, heat, and cooling. Unlike conventional cogeneration, it enables a reduction in cooling costs and an increase in overall system efficiency. In industries with high demand for process cooling, trigeneration often proves to be the most economical option, delivering significant cost savings and greater energy independence. Selecting the right unit requires a detailed analysis of the facility’s operating profile, but a properly designed installation is one of the most effective methods of reducing energy costs in the industrial sector.

What is trigeneration?

Trigeneration (Combined Cooling, Heat and Power – CCHP) is a system that produces three forms of energy:

- electricity,

- useful heat,

- cooling generated using an absorption or adsorption chiller.

In practice, a cogeneration unit (most commonly a gas engine or turbine) produces electricity and heat. Part of this heat is then directed to an absorption chiller, which converts thermal energy into cooling. As a result, the facility can simultaneously supply technological infrastructure, heat utilities or buildings, and provide cooling for production processes.

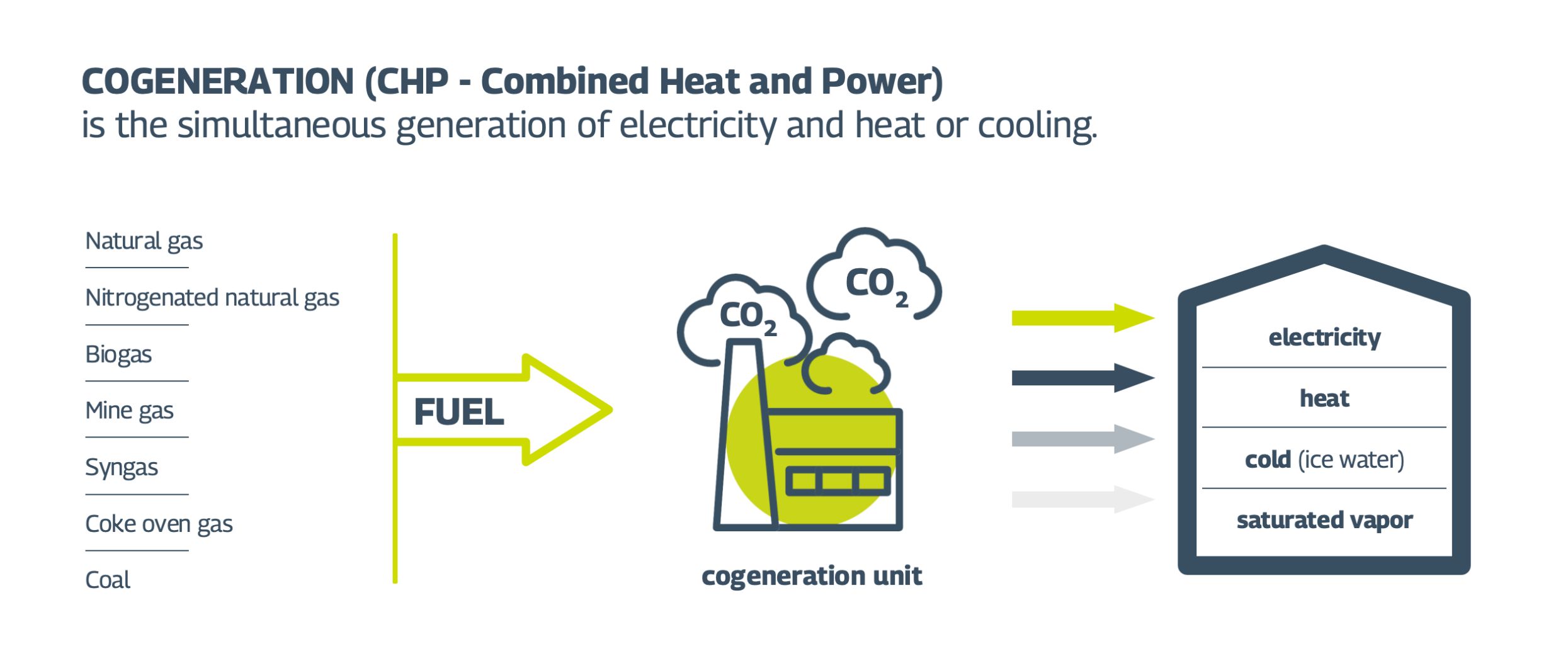

How does trigeneration differ from cogeneration?

Cogeneration enables the production of electricity and heat in a single process, increasing system efficiency. Trigeneration goes a step further—it uses part of the heat to produce cooling, which further improves fuel utilization efficiency, allows energy-intensive compression-based cooling systems to be replaced, and reduces electricity costs.

In many facilities, during the summer period, demand for cooling energy increases significantly, while demand for thermal energy decreases (for example, it is no longer used for space heating). Trigeneration makes it possible to maintain high operating efficiency of the unit even when thermal energy is not needed to its full extent, because the generated heat is converted into cooling energy. In cogeneration, unused thermal energy is simply lost, which reduces overall process efficiency.

Which industries benefit from trigeneration?

This technology is well suited to companies that simultaneously consume all three forms of energy - heat, cooling, and electricity. It is particularly useful where cooling represents a significant operating cost. Trigeneration is used in:

- food processing plants (refrigeration processes, cold storage, hall air conditioning),

- paper mills and pulp processing,

- chemical and pharmaceutical plants,

- plastics manufacturing facilities,

- the automotive industry (paint shops, injection molding),

- large logistics parks and data centers.

By using absorption chillers, the system becomes independent of traditional compression refrigeration units, which helps reduce electricity consumption.

When is it worth opting for trigeneration?

For trigeneration to be cost-effective, a facility must meet several key technical requirements. The most important include:

- steady and predictable electricity demand – the trigeneration unit should operate many hours per year, optimally over 6,000–7,000 hours. Low load or highly variable operating profiles can reduce profitability;

- year-round demand for heat – although part of the thermal energy can be directed to the absorption chiller, the facility should have stable demand for process or heating heat;

- high or seasonal demand for cooling – one of the most critical factors; trigeneration is profitable when cooling is required for production processes, air conditioning, or storage;

- ability to absorb thermal and cooling capacity – internal infrastructure must allow heat off-take and integration of an absorption chiller;

- access to competitively priced gaseous fuel – trigeneration systems typically operate on natural gas or biomethane, and fuel price strongly affects overall profitability;

- adequate space and installation location – gas engines, heat exchangers, exhaust systems, and absorption chillers require sufficient space and compliance with noise regulations.

Is cooling production in trigeneration more cost-effective than separate generation?

In most cases, yes - especially where cooling accounts for a significant share of operating costs. There are several reasons for this:

- absorption-based cooling requires very little electricity compared to standard compression chillers,

- waste heat from cogeneration is a by-product, so its use increases overall system efficiency,

- lower operating costs of absorption chillers—fewer mechanical components mean lower failure rates,

- increased annual utilization of the cogeneration unit, improving the economics of the entire investment.

Exceptions may include facilities with very low heat demand or irregular cooling load profiles - in such cases, the absorption system may not operate optimally. However, in most industrial plants, trigeneration replaces energy intensive cooling systems, leading to noticeable electricity savings.

How to select the right trigeneration unit?

Unit selection is the most challenging part of the entire process. Incorrect sizing can result in suboptimal operation and reduced investment efficiency. The primary factor to consider is the electricity consumption profile. Unit capacity should be matched to the minimum, not the maximum, electricity demand so that the unit can operate stably for most of the time.

Another key element is heat demand - an oversized unit generates excess heat that is difficult to utilize, while undersizing may limit cooling production. When determining the cooling capacity of the absorption chiller, it is essential to consider the amount of available heat as well as the seasonality and stability of technological processes.

In practice, industrial trigeneration units typically range from several hundred kilowatts of electrical capacity to several megawatts. Their selection should be based on a detailed audit of utility consumption and annual operational simulations, ensuring efficient system performance throughout the year.

Summary

Trigeneration is a comprehensive solution for industrial facilities seeking to reduce energy costs, improve energy efficiency, and limit environmental impact. By simultaneously producing electricity, heat, and cooling, energy can be used in the most efficient way possible, resulting in lower operating expenses and greater energy independence for the company.

The decision to implement trigeneration should be preceded by a detailed analysis of energy consumption, consideration of seasonal heat and cooling demand, and access to competitively priced fuel. Proper unit selection, effective integration with existing systems, and careful planning of annual operation allow savings to be maximized and energy losses minimized.