Industry 5.0 – characteristics and technologies

Industry 5.0 is the next era of industrial development that goes beyond the current framework of Industry 4.0. It is based on the implementation of new technologies and concepts that transform the operation of manufacturing companies. The key difference between these two models lies in the role of humans in the production process. While Industry 4.0 focused on automation, digitization, and machine integration, Industry 5.0 restores humans to a central role, emphasizing collaboration between people and technology as well as the customization of production.

What is industry 5.0?

The basic assumptions of Industry 5.0 were described in the report “Industry 5.0 – Towards a sustainable, human-centric and resilient European industry,” which was created after virtual workshops held in 2020. The meetings involved representatives of European research institutes and funding agencies, and discussions focused on the need to better consider the social and ecological priorities of the European Union in terms of technological innovation, shifting the emphasis from technology to a systemic and integrated approach.

What is the difference between industry 4.0 and industry 5.0?

Industry 5.0 does not replace Industry 4.0 but develops its assumptions. The European Commission notes that the fourth industrial revolution focused mainly on digitizing processes and using artificial intelligence to increase efficiency, which ultimately led to overlooking the role of employees and sustainable supply chain management. Industry 5.0 places humans at the center of the production process, where technology supports their activities. The goal is harmonious cooperation between people and machines, which differs from Industry 4.0, which focused on the interaction of IT systems and machines.

Industry 4.0 introduced concepts such as automation, artificial intelligence, the Internet of Things (IoT), and real-time data analysis. Thanks to these solutions, industrial companies could increase production efficiency, reduce costs, and improve effectiveness. However, the key goal was process optimization and minimizing the role of humans in production.

Industry 5.0 represents the next development stage, with a more humanistic approach. The most important assumption is close cooperation between humans and robots, as well as a greater emphasis on product personalization, sustainable development, and ethical practices in production processes.

What are the technologies of industry 5.0?

Industry 5.0 technologies enable harmonious cooperation between humans and machines, as well as create the foundation for more ecological and personalized production processes. It is a combination of technologies developed within Industry 4.0 with an emphasis on two additional pillars: sustainable development and the human aspect. Here are the most important technologies related to Industry 5.0:

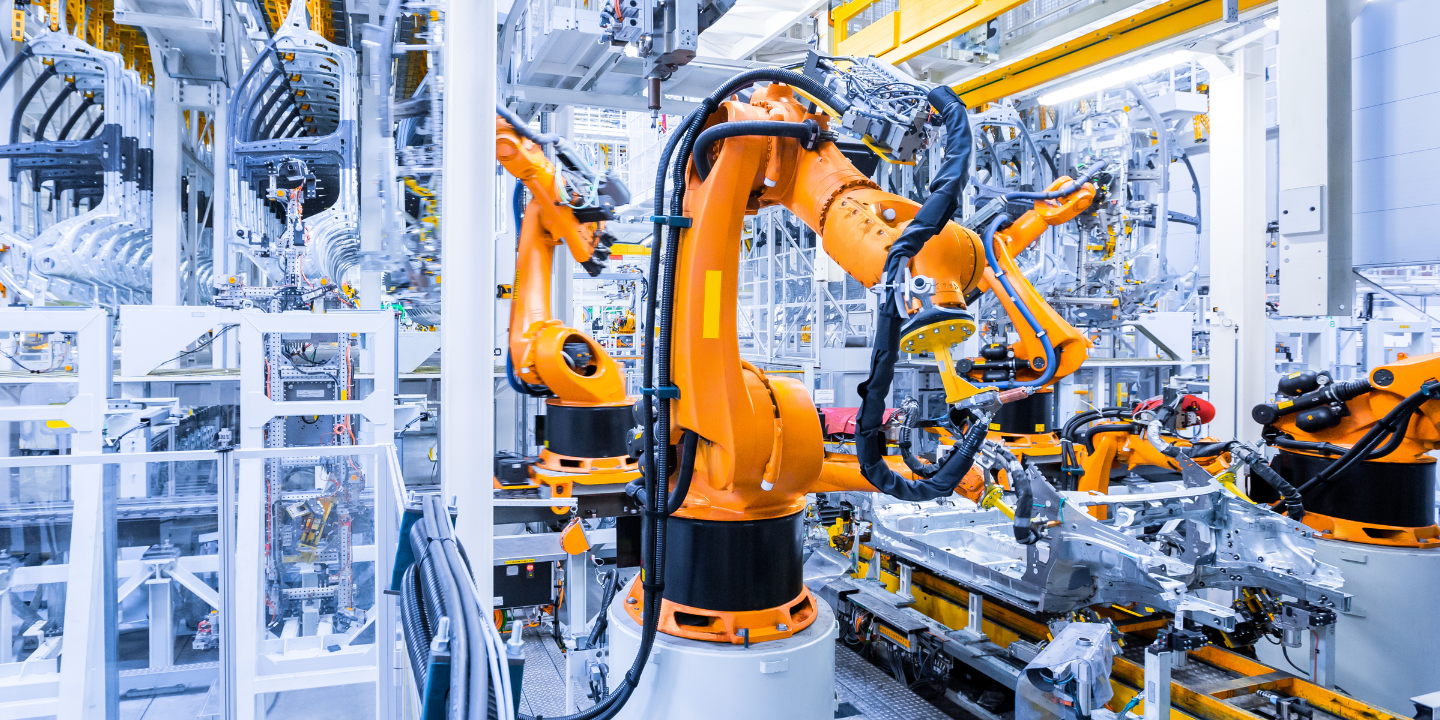

Collaborative robots (cobots)

Cobots are robots designed to work directly with humans, supporting them in performing precise and complex tasks. Unlike traditional industrial robots, cobots are safe in the human work environment, which increases the efficiency and flexibility of production processes, allowing them to be tailored to individual customer needs.

Artificial intelligence (AI) and machine learning (ML)

Artificial intelligence is mainly applied in data analysis and production process optimization in Industry 5.0. AI and ML allow machines to make intelligent decisions based on huge amounts of data, enabling dynamic adaptation of production to changing conditions and requirements.

Augmented reality (AR) and virtual reality (VR)

AR and VR technologies support employees by enabling more effective training and remote operation and repair of machines. AR allows visualization of production data in real time, speeding up decision-making and reducing response time to technical issues.

Internet of Things (IoT)

The Internet of Things (IoT) connects machines and systems into intelligent networks, enabling their mutual communication. IoT provides monitoring and optimization of production processes in real time, also supporting energy consumption management and promoting sustainable development.

Big data and real-time data analysis

Thanks to data analysis, Industry 5.0 enables predicting failures, optimizing production, and reducing losses. Big data allows companies to better understand their processes and adapt more quickly to changing market needs.

Sustainable technologies

Sustainable development is one of the pillars of Industry 5.0. Increasing emphasis is placed on technologies that reduce energy consumption and CO2 emissions. Industry 5.0 promotes energy-efficient solutions, renewable energy sources, and a circular economy.

Take a step towards cost-effective decarbonization of your business

Contact usWhat does industry 5.0 change in industrial companies?

Industry 5.0 opens many new opportunities for industrial companies. Cooperation between humans and technology enables the introduction of more innovative solutions and accelerates decision-making. Technologies from Industry 5.0, such as sustainable energy systems, can attract customers looking for environmentally responsible partners. Companies that adopt this approach will gain not only in terms of image but also financially, thanks to savings resulting from better resource management and reduced energy consumption.

Summary

Industry 5.0 is the future that combines advanced technologies with humans and a sustainable approach to production. Companies that implement these innovations can expect a range of benefits—from product personalization and higher energy efficiency to improved reputation in the eyes of customers and business partners.

For companies operating in the field of energy efficiency and zero-emission investments, Industry 5.0 creates huge opportunities to increase competitiveness and adapt to increasingly demanding market standards. Proper technology selection and appropriate implementation management are key steps that will allow companies to succeed in this new, fifth era of industry.