Greater production and lower emissions – Umicore on the way to net zero

The Umicore team at the Jiangmen plant prepared a zero-emission strategy with the audit company, which did not meet its expectations. Umicore asked us, and our engineering team developed a specific path to reduce emissions by 70% within 4 months. Although in our latest projects we focus mainly on designing and implementing energy-saving investments, in this case we used our competencies primarily in consulting activities. The client has already started implementing the strategy we developed and, among others, reduced steam consumption in his plant by 50%.

First step

The goal of the Umicore plant in Jiangmen was to reduce the consumption of thermal energy contained in steam and condensate. With a strong commitment to environmental protection in its DNA, the company has strived to minimize emissions, with a plan to achieve zero emissions by 2035.

Before working with us, the Umicore team undertook to develop an emission reduction strategy with another company offering audit services. Unfortunately, its strategic goals were not met. Thanks to our cooperation with EFESO, the client came to us, and we met his expectations within 4 months!

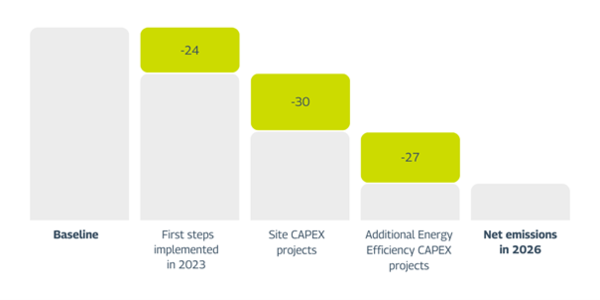

We developed a CO₂ reduction map that met the client's key goals. The plant was preparing for the planned doubling of production in 2024-2025. Our roadmap has enabled Umicore to increase production capacity while reducing emissions and energy consumption. Importantly, our strategy did not interfere with production processes, which was crucial for the plant.

Implementation of the project

The engineering team's expertise identified several places where energy losses occurred and which would cover the heat demand in the main process. The key activities at the plant were heat recovery from air compressors and heat recovery from wastewater.

The Jiangmen plant used higher parameters, such as higher steam temperatures, than necessary in some places, leading to higher costs and losses. Both the client's team and the audit company previously working with him overlooked solutions that would allow the client to reduce greenhouse gas emissions by 70% if he followed the guidelines we developed.

Reduction of CO2 resulting from the steam production expressed on % of baseline for CO2 in 2026

Main challenge

One of the client's motivations to start the path to zero-emission was the company's activities in the automotive industry, where many stakeholders pay particular attention to activities that reduce the harmful impact of business on the environment. An important aspect of Umicore's activity is circularity, which is reflected in the industry in which the company operates - recycling of batteries, catalytic converters and critical materials.

Effects

- A precise and understandable zero-emission strategy for the client, created in 4 months

- Steam consumption reduced by 50% after implementing the first steps of the roadmap

- By 2030: reduction of CO2 equivalent emissions per tonne of product purchased by 42%

- By 2035: Net zero emissions

Umicore is a global group in the chemical industry. This company, with 45 production plants, is a leader in the recycling of batteries and critical raw materials. The Jiangmen plant is located in southern China and has been operating since 2006.